מפעל 재활וץ פלסטיק

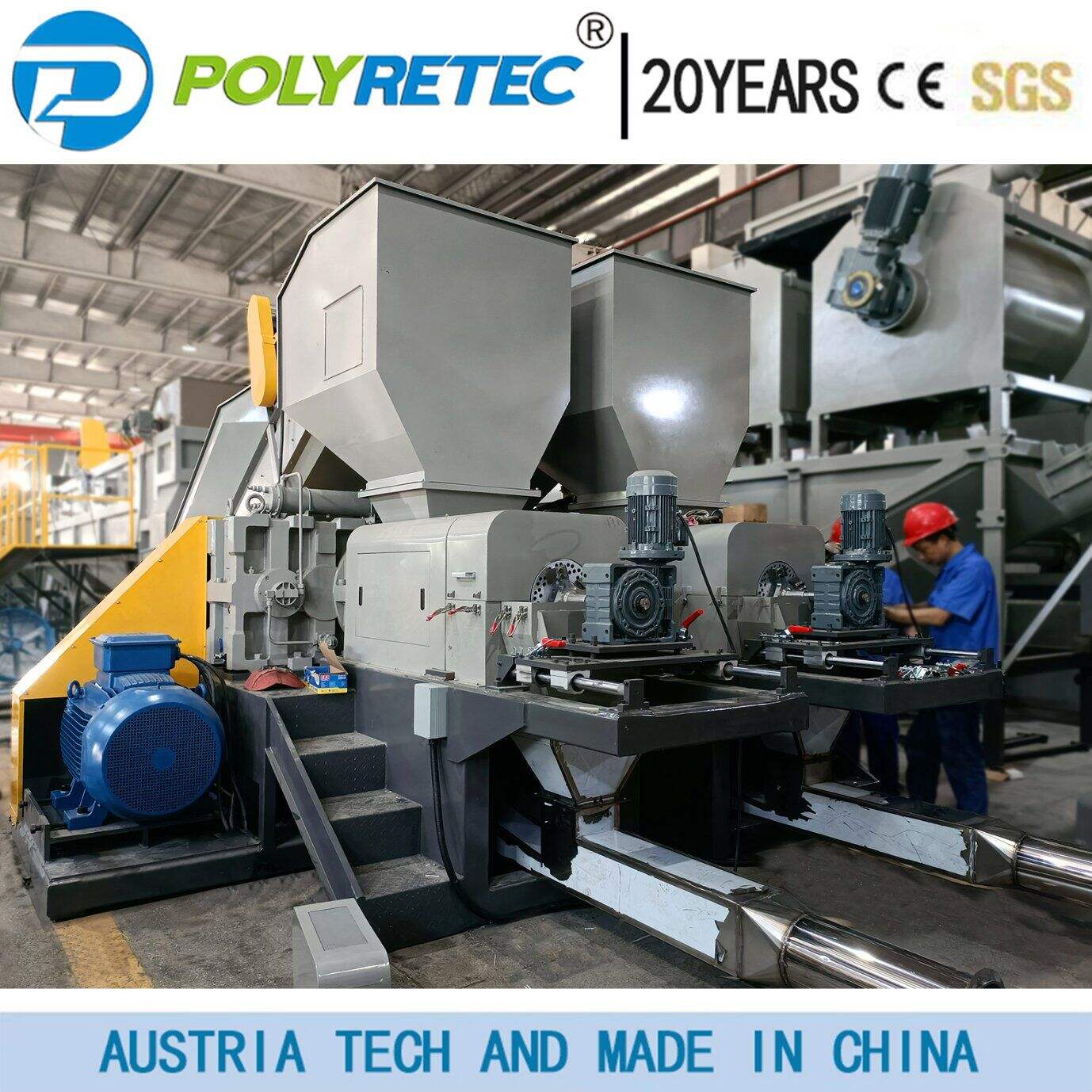

מפעל מיחזור פלסטיק הוא מתקנה תעשייתית מתוחכמת שנועד להפוך פסולת פלסטיק לחומרים שניתן להשתמש בהם שוב באמצעות סדרה של צעדי עיבוד מתקדמים. המפעל כולל מערכות מיון מתקדמות, יחידות כביסה ומכונות חיתוך כדי לטפל בצורה יעילה בסוגי פסולת פלסטיק שונים. במרכזו, המתקן משתמש בטכנולוגיה מעוצבת אוטומטית המשתמשת בחיישנים אופטיים ובבינה מלאכותית לזהות ולבדיל סוגים שונים של פלסטיק, להבטיח התאוששות מקסימלית של חומר. מערכת הכביסה מסירה מזהמים ומכינה את החומרים לעיבוד, בעוד ציוד הגירוב מקטין את פריטי הפלסטיק לגדלים אחידים לעיבוד אופטימלי. מערכת החץ של המפעל מותכת ומחזירה את הפלסטיק המעובד לפללים או דגלים, מוכנים לייצור מוצרים חדשים. אמצעי בקרה מתקדמים של איכות, כולל מערכות ניטור בזמן אמת ובדיקות מעבדה, מבטיחים שההוצאה עומדת בסטנדרטים בתעשייה. המתקן יכול לעבד סוגים רבים של פלסטיק, כולל PET, HDPE, LDPE ו- PP, עם קיבולת יומית הנעה בין 5 ל -50 טון, בהתאם לתיצור. מערכות בקרה סביבתיות מנהלות פליטות וטיפול במים, מה שהופך את הפעילות אחראית לסביבה תוך שמירה על יעילות גבוהה.