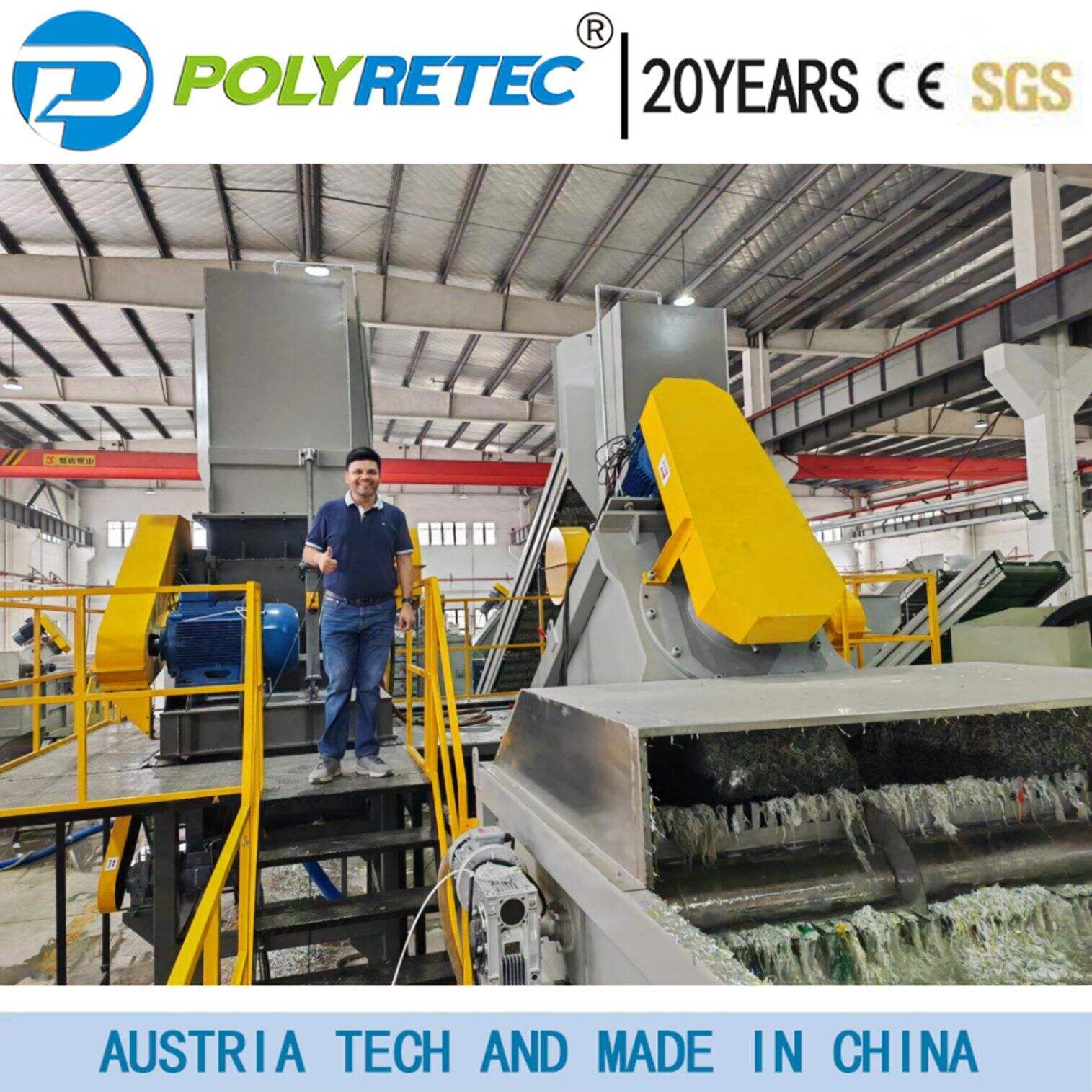

מכונה לגראנולציה של חיות

מכונת פלטת חיות מחמד представляет פתרון מתקדם בטכנולוגיית 재ציקל פלסטיק, והיא נועדה במיוחד לעיבוד חומרים מסוג PET (פוליאתילן טרפת'לט) לפלטת באיכות גבוהה. המערכת המתקדמת הזו כוללת קו עיבוד מקיף שמתחיל עם הזנת החומר ועובר דרך מספר שלבים כולל חימום, אקסטורוזה, קירור וגזירה. המכונה משתמשת במערכות שליטה מדויקות בטמפרטורה ובעיצובים מיוחדים של ברגים כדי להבטיח נמס וערבוב אידיאליים של חומרי ה-PET, מה שמוביל לייצור אחיד של פלטת. מערכת הפעלה אוטומטית שלה שומרת על קצב ייצור קבוע תוך מיצוי פרמטרים קריטיים כמו לחץ, טמפרטורה ומהירות גזירה. המכונה יכולה לעבד צורות שונות של חומרי PET, כולל בקבוקים, מיכלים ושאריות תעשייה, ומעבירה אותם לפלטת המתאימה לחידוש שימוש בייצור. עם קיבולת ייצור הנעה בין 100 ל-1000 ק"ג לשעה, ניתן להתאים את המכונות כדי לעמוד בדרישות תעשומיות שונות. שילוב של מערכות סינון מתקדמות מבטיח הסרת זיהומים, בעוד מערכת הקירור במים ממצה את החומר המוזן במהירות כדי לאפשר גזירה אחידה ומדויקת לפלטת אחידה.