Understanding the Role of CE Certification in Plastic Machinery Exports

What Is CE Certification and Why It Matters

CE certification is a regulatory mark required for a wide range of products sold within the European Economic Area (EEA). For manufacturers involved in the production and export of plastic recycling machinery, CE certification plays a crucial role in confirming that their equipment complies with EU health, safety, and environmental protection standards. This mark is not merely a label—it is a gateway to accessing European markets legally and competitively. Machinery without CE certification cannot be sold or operated within the EU, making it essential for any business involved in the export of plastic machine equipment. The certification process involves several stages including risk assessment, conformity evaluation, and the creation of technical documentation. It also requires manufacturers to affix the CE mark visibly on their machines, indicating that the product has passed all necessary compliance checks. Obtaining CE certification is a strategic move for companies aiming to expand into Europe, increase consumer trust, and ensure operational safety.

How CE Certification Impacts Plastic Recycling Machinery

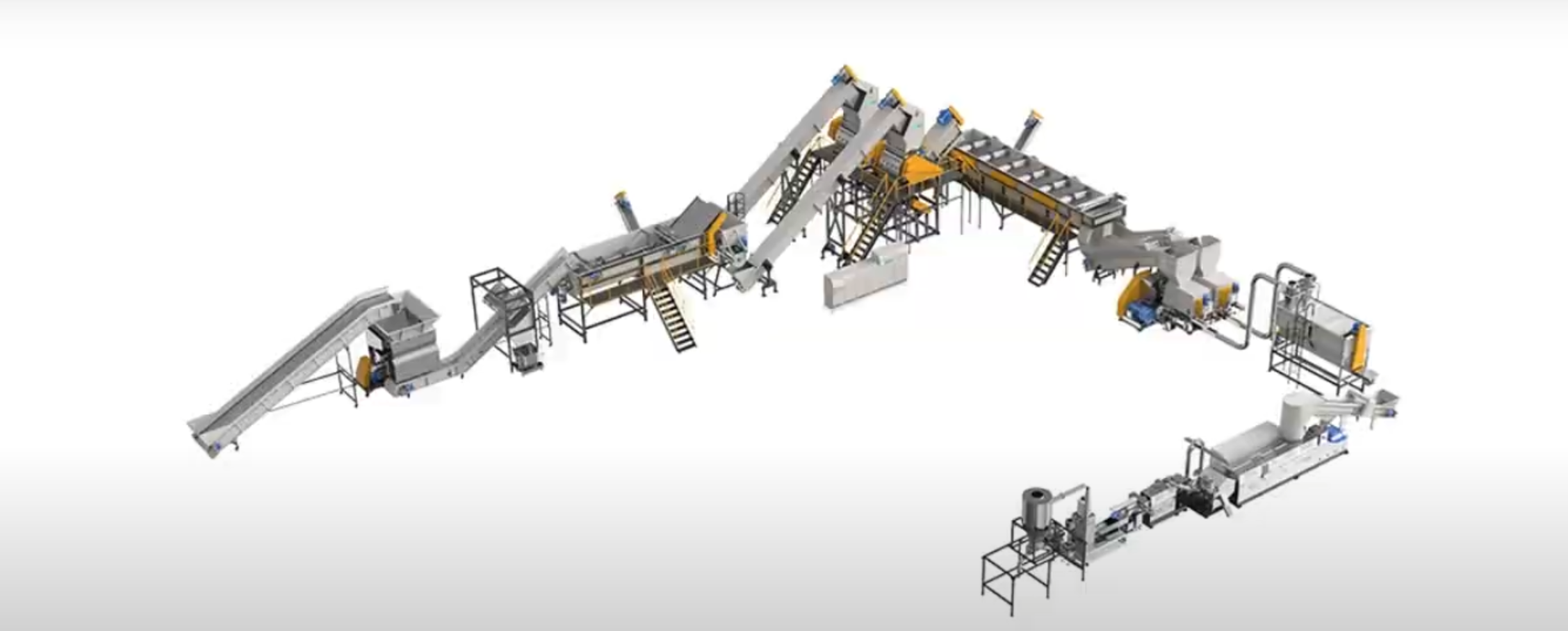

Plastic recycling machinery is often large, complex, and energy-intensive, which makes regulatory compliance particularly critical. CE certification ensures that these machines meet strict safety and environmental guidelines that protect both operators and the ecosystem. For export plastic machine manufacturers, aligning with CE standards demonstrates a commitment to quality, operational efficiency, and sustainable industrial practices. The certification covers aspects such as mechanical stability, fire resistance, noise control, and emissions management. CE certification also requires comprehensive documentation, including user manuals, installation guidelines, and maintenance protocols. These documents must be clear, detailed, and written in the appropriate EU languages to be accepted. For businesses involved in export plastic machine production, mastering these documentation requirements can streamline the approval process and avoid costly delays. Another key impact is that CE certification fosters innovation in product design.

Preparing Your Plastic Recycling Equipment for CE Certification

Steps Involved in the CE Certification Process

Preparing plastic recycling machinery for CE certification is a structured and detailed process. The first step is to determine which EU directives and regulations apply to your specific machinery. These may include the Machinery Directive, the Low Voltage Directive, the EMC Directive, and potentially the RoHS or EcoDesign directives. Once identified, manufacturers must conduct a thorough risk assessment to identify potential hazards related to machine operation, maintenance, and failure scenarios. This analysis forms the basis for selecting appropriate safety measures and design modifications. Next, technical documentation must be assembled. This documentation includes engineering drawings, electrical schematics, a bill of materials, compliance declarations, test results, and detailed user instructions. Each document must be precise, accurate, and up to date.

Common Mistakes to Avoid During Certification

One of the most common mistakes in the CE certification process is underestimating the importance of early planning. Many manufacturers in the export plastic machine industry wait until production is nearly complete before considering CE compliance, leading to costly redesigns or delays. Starting the process early allows time to integrate safety measures and generate documentation alongside product development. Another frequent oversight is incomplete or poorly organized technical documentation. Missing or incorrect data can result in immediate rejection or the need for extensive rework. Using outdated standards is another trap—CE regulations are periodically updated, and staying informed is critical for ongoing compliance. Some businesses rely heavily on self-declaration when third-party testing is actually required for certain machinery categories. This mistake can result in non-compliant products reaching the market, leading to legal and financial repercussions.

Key CE Certification Requirements for Plastic Recycling Machinery

Safety Standards and Risk Assessment

One of the core elements of CE certification for plastic recycling machinery is adherence to safety standards and comprehensive risk assessment. This process involves identifying all potential hazards associated with the machinery, from mechanical injuries to electrical risks and chemical exposure. Manufacturers in the export plastic machine industry must take proactive measures to eliminate or mitigate these risks through design improvements, safety guards, interlock systems, and emergency stop functions. The assessment also evaluates the safety of components such as motors, sensors, conveyors, and shredding mechanisms. Compliance with ISO and EN standards ensures that the machinery meets universally recognized benchmarks. CE certification mandates that a risk assessment be documented thoroughly and integrated into the technical file. This documentation must describe the identified risks, the actions taken to mitigate them, and the rationale behind each decision.

Electrical and Electromagnetic Compliance

Another crucial aspect of CE certification for plastic recycling machinery is ensuring electrical and electromagnetic compliance. All electrical systems within the machinery must adhere to the Low Voltage Directive (LVD), which governs the safety of electrical equipment operating within specific voltage ranges. Proper insulation, grounding, wiring, and circuit protection must be in place to prevent electric shock, fire, and other hazards. In addition to meeting electrical safety requirements, machines must also comply with the Electromagnetic Compatibility (EMC) Directive. This regulation ensures that the equipment neither emits excessive electromagnetic interference (EMI) nor is unduly affected by it. For export plastic machine manufacturers, compliance with EMC standards helps maintain functional stability when machinery is operated near other industrial systems.

Documentation and Quality Control Strategies

Essential Technical File Components

A successful CE certification process relies heavily on comprehensive and accurate technical documentation. The technical file serves as the backbone of compliance, detailing the machine’s design, construction, operation, and safety measures. For manufacturers in the export plastic machine industry, the technical file must include several mandatory documents such as general assembly drawings, electrical schematics, a bill of materials, software algorithms (if applicable), test reports, and declarations of conformity. These documents provide evidence that the machinery meets all relevant EU directives and harmonized standards. Each document should be clear, organized, and easily accessible for audits or customer reviews. In addition to the core documents, the file must also contain a risk assessment report, instructions for safe installation and operation, maintenance schedules, and a list of standards applied.

Implementing Internal Quality Control Measures

To complement robust documentation, manufacturers must implement effective internal quality control measures. These systems ensure that every unit of machinery produced adheres to the same high standards set during CE certification. Quality control processes begin with supplier evaluations, ensuring that all materials and components meet specification. Incoming inspections, in-process checks, and final product tests are also integral parts of a comprehensive quality control strategy. For companies in the export plastic machine industry, these measures reduce variability, improve product consistency, and minimize defects. A well-defined quality management system (QMS) aligned with ISO 9001 standards can significantly enhance CE compliance efforts.

Post-Certification Responsibilities and Market Strategy

Maintaining Compliance After Market Entry

Securing CE certification is not the end of the compliance journey. Once the machinery is placed on the European market, manufacturers must ensure ongoing conformity with applicable directives and standards. This means monitoring changes in EU regulations and updating designs, documentation, and safety measures accordingly. For companies engaged in export plastic machine production, maintaining compliance requires continuous vigilance and proactive adaptation. Periodic internal reviews, re-testing, and customer feedback analysis help detect emerging risks or regulatory gaps. Any significant design modification or performance enhancement must be evaluated for its impact on compliance and may necessitate a new CE assessment.

Leveraging CE Certification for Business Growth

Beyond regulatory compliance, CE certification can be a powerful marketing tool that enhances brand image and drives business growth. Displaying the CE mark signals to buyers that the machinery meets high standards of safety, quality, and performance. This boosts customer confidence and increases the likelihood of securing contracts in competitive tenders and government procurements. For export plastic machine companies, highlighting CE certification in marketing materials, product catalogs, and trade shows can attract European buyers and open new distribution channels. It can also facilitate partnerships with OEMs, integrators, and large-scale recyclers who prioritize certified equipment.

FAQ

What is CE certification and why is it necessary for plastic recycling machines

CE certification is a legal requirement for machinery sold within the European Economic Area. It verifies that the equipment complies with relevant EU directives on safety, health, and environmental protection. For plastic recycling machines, it ensures reliable operation, worker safety, and eligibility for European market access.

How long does the CE certification process take for export plastic machines

The timeline can vary depending on the complexity of the machinery and the readiness of technical documentation. On average, it can take anywhere from 2 to 6 months. Early planning and working with experienced consultants can help shorten this timeframe.

Can a manufacturer self-certify their plastic recycling equipment

In some cases, self-certification is allowed, particularly for low-risk machinery. However, most plastic recycling machines require third-party involvement due to their complexity and potential hazards. It’s important to consult EU directives to determine the correct route.

What happens if a non-compliant machine is exported to the EU

Non-compliant machines can be seized, banned from sale, or recalled. The manufacturer may face legal penalties, damaged reputation, and financial losses. Ensuring CE compliance before export is essential for avoiding these risks.

Table of Contents

- Understanding the Role of CE Certification in Plastic Machinery Exports

- Preparing Your Plastic Recycling Equipment for CE Certification

- Key CE Certification Requirements for Plastic Recycling Machinery

- Documentation and Quality Control Strategies

- Post-Certification Responsibilities and Market Strategy

- FAQ