The Evolution of Advanced Film Recycling Technology

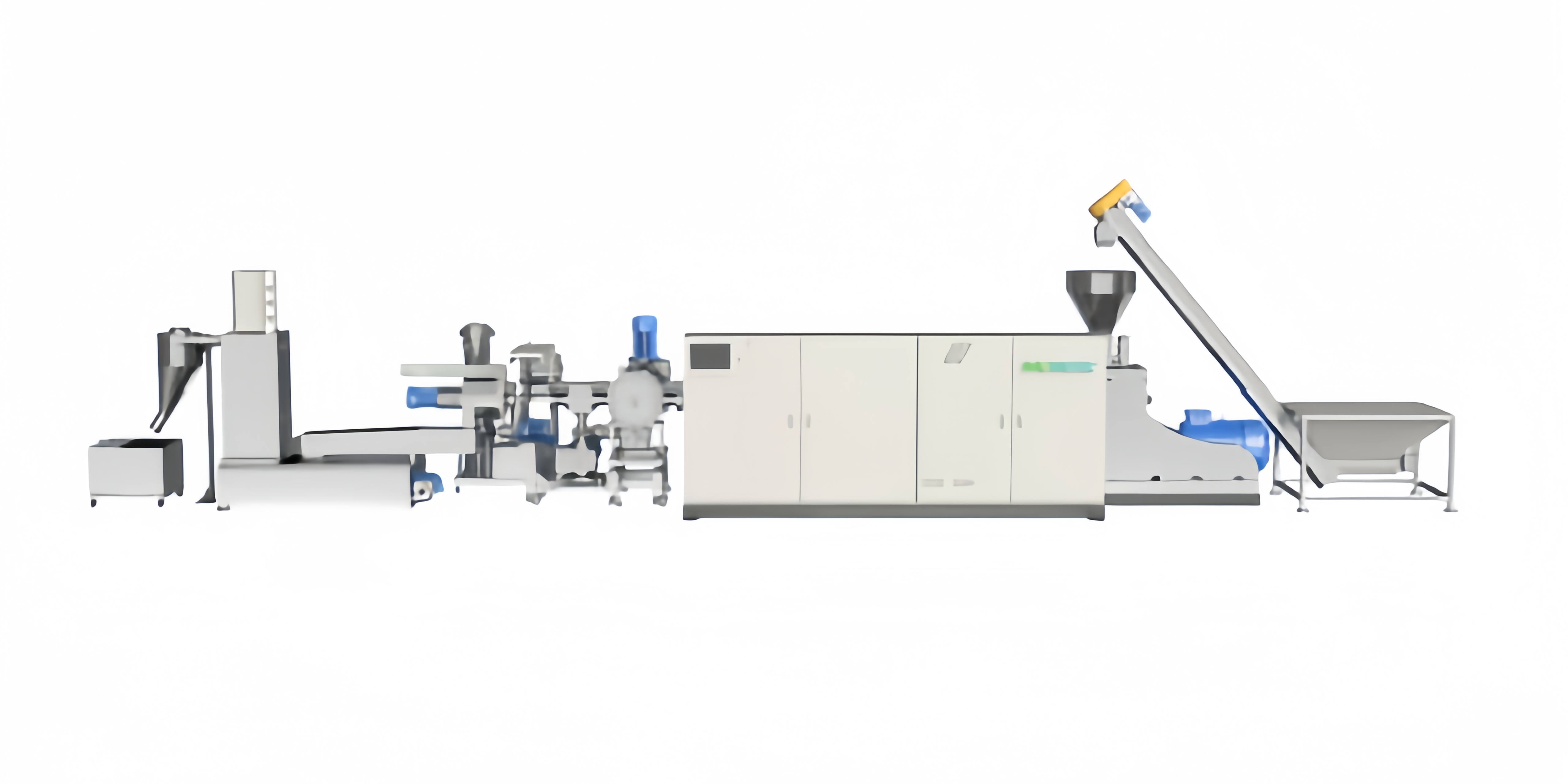

The landscape of plastic recycling has transformed dramatically over the past decade, with film recycling machines emerging as crucial components in sustainable waste management. These sophisticated systems have revolutionized how we process and recycle plastic films, offering efficient solutions for environmental challenges while creating valuable resources from waste materials.

Modern film recycling machines represent the culmination of years of technological advancement and engineering innovation. They combine robust mechanical systems with smart controls to process various types of plastic films, from agricultural waste to post-consumer packaging materials. The latest machines deliver unprecedented efficiency levels while maintaining strict quality standards for the recycled output.

Core Components and Operational Excellence

Advanced Feeding and Sorting Systems

The heart of any film recycling machine begins with its feeding mechanism. Modern systems incorporate automatic feeding systems with variable speed controls, allowing for consistent material flow while preventing jamming. These sophisticated feeders can handle multiple types of film materials simultaneously, from lightweight shopping bags to thicker industrial packaging films.

Smart sorting technology integrates optical sensors and artificial intelligence to identify and separate different types of plastic films. This ensures maximum purity in the recycled output and reduces contamination risks. The sorting system can detect and remove non-plastic materials, ensuring only appropriate materials enter the processing stage.

Cutting-Edge Shredding Technology

The shredding component of a film recycling machine employs hardened steel blades designed for optimal cutting efficiency. Modern machines feature adjustable cutting speeds and customizable blade configurations to handle various film thicknesses and compositions. The precision-engineered cutting chamber ensures uniform size reduction while minimizing heat generation and energy consumption.

Advanced wear-resistant materials extend blade life and reduce maintenance requirements, while automatic sharpening systems maintain consistent cutting performance. The latest models also incorporate safety features that automatically stop operation if foreign objects are detected, protecting both the equipment and operators.

Processing and Quality Control Features

Washing and Decontamination Systems

Modern film recycling machines integrate sophisticated washing systems that effectively remove contaminants while minimizing water consumption. Multi-stage washing processes utilize specialized detergents and friction washing technology to ensure thorough cleaning of processed materials. Advanced water filtration and recycling systems reduce environmental impact while maintaining optimal cleaning efficiency.

Decontamination units employ both mechanical and chemical processes to remove adhesives, inks, and other impurities. Temperature-controlled washing cycles optimize cleaning effectiveness while preventing material degradation. These systems often include automatic pH monitoring and adjustment capabilities to maintain ideal washing conditions.

Drying and Moisture Control

Efficient moisture removal is crucial for quality recycled output. Contemporary film recycling machines feature high-performance drying systems that combine mechanical and thermal drying processes. Centrifugal dryers remove bulk moisture, while hot air systems ensure thorough drying of processed materials.

Advanced moisture sensors continuously monitor material moisture content, automatically adjusting drying parameters to maintain optimal conditions. Energy-efficient heat recovery systems reduce operating costs while ensuring consistent drying performance across various material types.

Automation and Control Systems

Smart Operation Management

Modern film recycling machines leverage sophisticated control systems that optimize performance while minimizing operator intervention. Touch-screen interfaces provide intuitive access to all machine functions, while integrated PLCs (Programmable Logic Controllers) ensure precise control over every processing stage.

Real-time monitoring systems track key performance indicators, allowing operators to identify and address potential issues before they impact production. Remote monitoring capabilities enable offsite supervision and troubleshooting, reducing downtime and maintenance costs.

Data Analytics and Reporting

Advanced analytics capabilities help operators optimize machine performance and track recycling efficiency. Built-in reporting systems generate detailed production data, including throughput rates, energy consumption, and material quality metrics. This information enables data-driven decision-making for process improvement and maintenance planning.

Cloud connectivity allows for seamless data sharing across facilities and integration with enterprise management systems. Machine learning algorithms analyze operational data to predict maintenance needs and optimize processing parameters automatically.

Environmental and Safety Features

Emission Control and Energy Efficiency

Environmental responsibility is a key focus of modern film recycling machines. Advanced filtration systems capture and control dust and fumes, ensuring safe working conditions and minimal environmental impact. Energy-efficient motors and drives reduce power consumption while maintaining optimal performance levels.

Heat recovery systems capture and reuse thermal energy from various processing stages, improving overall energy efficiency. Variable frequency drives adjust power consumption based on actual processing requirements, optimizing energy usage during different operational phases.

Operator Safety and Ergonomics

Contemporary film recycling machines incorporate comprehensive safety features to protect operators. Emergency stop systems, safety interlocks, and protective guards ensure safe operation, while ergonomic design elements reduce operator fatigue and improve accessibility for maintenance.

Advanced noise reduction features create a more comfortable working environment, while dust collection systems maintain air quality around the machine. User-friendly control interfaces minimize the risk of operator error while maximizing productivity.

Frequently Asked Questions

What is the typical processing capacity of a modern film recycling machine?

Modern film recycling machines offer varying capacities to suit different operational needs, typically ranging from 500 to 3000 kg per hour. The actual processing capacity depends on factors such as material type, contamination levels, and desired output quality. Advanced machines can maintain consistent throughput rates while adapting to varying input conditions.

How does a film recycling machine handle different types of plastic films?

Advanced film recycling machines utilize adjustable processing parameters and specialized components to handle various film types. The machines can process different materials by automatically adjusting cutting speeds, washing temperatures, and other operational parameters. Sophisticated sorting systems ensure proper separation of different film types before processing.

What maintenance requirements should be expected for a film recycling machine?

While modern film recycling machines are designed for reliability, regular maintenance is essential for optimal performance. Key maintenance activities include blade sharpening or replacement, cleaning of washing and filtration systems, and inspection of wear components. Predictive maintenance features help schedule service activities to minimize operational disruption.