Essential Guide to Selecting Industrial Recycling Machinery

The growing environmental consciousness and strict regulations have made plastic recycling equipment an integral part of modern waste management. Selecting the right machinery requires careful consideration of multiple factors, from material types to processing capacity. This comprehensive guide will help you navigate the complex world of recycling technology and make informed decisions for your facility.

Understanding Different Types of Plastic Recycling Systems

Primary Processing Equipment

At the forefront of any recycling operation are the primary processing machines. These include shredders, granulators, and washers that handle the initial breakdown of plastic materials. Shredders are particularly crucial for processing larger items like industrial containers and automotive parts, while granulators excel at creating uniform particle sizes essential for subsequent processing stages.

Modern plastic recycling equipment often incorporates advanced sensor technology to detect and remove contaminants during this initial phase. This technology significantly improves the quality of the final recycled material and reduces maintenance requirements downstream.

Secondary Processing Solutions

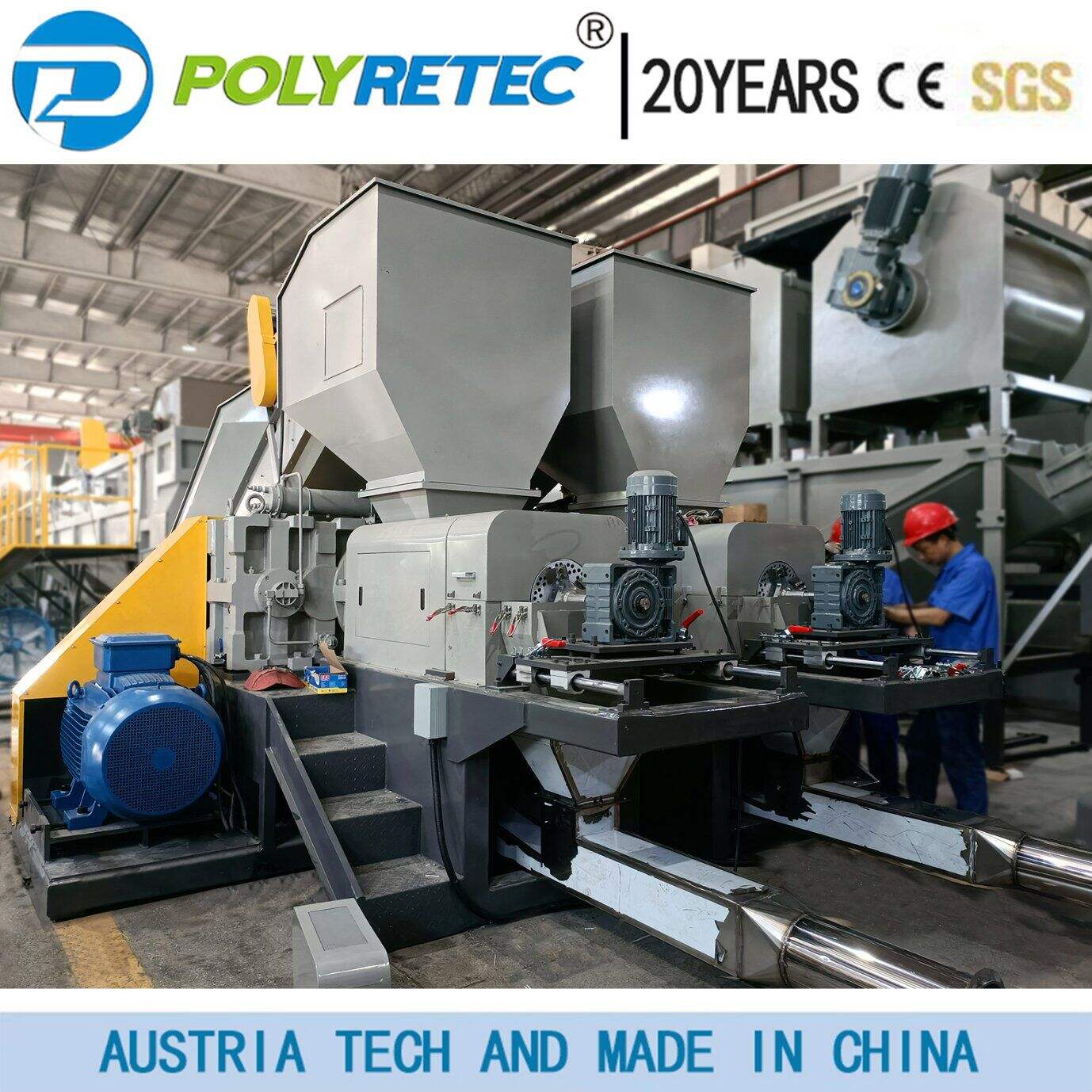

After initial size reduction, secondary processing equipment takes center stage. This category includes extruders, pelletizers, and compounding systems. These machines transform processed plastic flakes into usable raw materials for manufacturing. The choice of secondary equipment largely depends on your end product specifications and market demands.

Advanced extrusion systems can handle multiple polymer types and produce consistent quality pellets. Some modern plastic recycling equipment features automated sorting capabilities, ensuring maximum material recovery and minimal waste.

Material-Specific Considerations

Equipment for Thermoplastics

Thermoplastics, including PET, HDPE, and PP, require specific processing parameters. The plastic recycling equipment must maintain precise temperature control to prevent material degradation. Modern systems incorporate advanced heating and cooling mechanisms to optimize processing conditions for different thermoplastic types.

For instance, PET recycling demands specialized crystallization and solid-state polymerization equipment to achieve food-grade quality. The machinery must handle varying intrinsic viscosity levels while maintaining product consistency.

Engineering Plastics Processing

Engineering plastics like ABS, PC, and nylon present unique challenges in recycling. These materials often require more robust plastic recycling equipment with enhanced wear resistance and precise temperature control. The machinery must handle higher processing temperatures and potential corrosive additives commonly found in engineering plastics.

Advanced filtration systems become crucial when processing these materials to remove contaminants and maintain end product quality. The equipment should also accommodate various additive systems for property enhancement during recycling.

Operational Efficiency and Automation Features

Smart Control Systems

Modern plastic recycling equipment increasingly incorporates smart control systems and IoT capabilities. These features enable real-time monitoring of processing parameters, predictive maintenance scheduling, and automated quality control. The integration of artificial intelligence helps optimize operation parameters and reduce energy consumption.

Remote monitoring capabilities allow operators to adjust settings and troubleshoot issues from anywhere, improving overall equipment effectiveness and reducing downtime. These smart systems can also generate detailed production reports and material tracking data.

Energy Efficiency Solutions

Energy consumption significantly impacts operating costs in plastic recycling operations. Latest-generation plastic recycling equipment features energy-efficient motors, optimized heating systems, and regenerative drive technology. These innovations can reduce power consumption by up to 30% compared to conventional systems.

Advanced heat recovery systems capture and reuse thermal energy from the processing operations, further improving overall efficiency. The equipment's design should prioritize insulation and heat management to minimize energy losses during operation.

Capacity Planning and Scalability

Throughout Considerations

Selecting plastic recycling equipment with appropriate throughput capacity is crucial for operational success. The machinery should handle current volume requirements while providing room for future growth. Modern systems offer modular designs that facilitate capacity expansion without complete system replacement.

Consider peak processing demands and seasonal variations when specifying equipment capacity. The system should maintain consistent performance even during high-demand periods while operating efficiently during normal conditions.

Future-Proofing Your Investment

The recycling industry continues to evolve with new technologies and regulations. Choosing plastic recycling equipment that can adapt to future requirements helps protect your investment. Look for systems with upgradeability options and compatibility with emerging recycling technologies.

Consider equipment that can process multiple material types and grades, providing flexibility as market demands change. The ability to integrate new features and technologies through software updates adds long-term value to the investment.

Frequently Asked Questions

What maintenance requirements should I consider when selecting plastic recycling equipment?

Regular maintenance is crucial for optimal performance. Look for equipment with easily accessible wear parts, automated lubrication systems, and predictive maintenance capabilities. Consider the availability of spare parts and local service support when making your selection.

How can I determine the right size of plastic recycling equipment for my facility?

Assess your current and projected material volumes, available space, and utility capabilities. Consider peak processing requirements and factor in potential growth. Consulting with equipment manufacturers can help determine the optimal size based on your specific needs.

What safety features should plastic recycling equipment include?

Essential safety features include emergency stop systems, safety interlocks, proper guarding, and dust collection systems. Modern equipment should comply with current safety standards and include advanced features like automatic shutdown systems and operator safety protocols.