The Transformative Impact of Modular Design on Recycling Operations

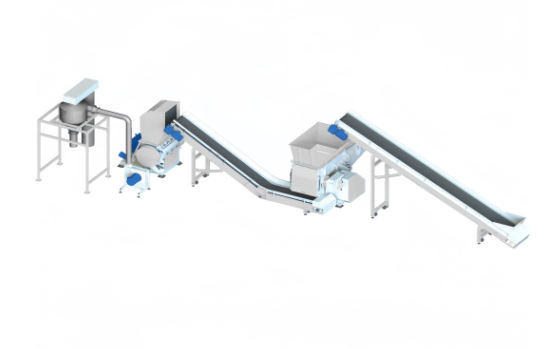

Modular systems are revolutionizing plastic recycling operations by introducing unprecedented adaptability to changing material streams and market demands. These prefabricated, scalable units allow recycling facilities to adjust their processing capacity and capabilities with remarkable efficiency. The inherent flexibility of modular systems enables operators to respond to fluctuations in feedstock volume, composition, and quality without costly facility modifications. Unlike traditional fixed recycling plants, modular systems can be reconfigured, expanded, or relocated as business needs evolve. This adaptability makes modular systems particularly valuable in today's dynamic recycling environment where material availability and market conditions change rapidly. The plug-and-play nature of modular systems reduces installation time and capital requirements while maintaining high processing standards.

Rapid Deployment and Scalability

Quick Installation Advantages

Modular systems dramatically reduce the time required to establish functional recycling capacity compared to conventional plant construction. Pre-engineered modular systems arrive at the site with most components pre-assembled and tested, slashing installation time by 50-70%. This rapid deployment capability allows recycling operators to capitalize on emerging opportunities or respond to urgent waste management needs. The standardized interfaces of modular systems ensure consistent performance regardless of installation location or configuration. Many modular systems can be operational within weeks rather than the months or years required for traditional recycling plant construction. This speed-to-market advantage makes modular systems ideal for pilot projects, temporary operations, or rapid capacity expansion.

Gradual Capacity Expansion

The scalable nature of modular systems enables recycling businesses to grow their processing capacity in line with actual demand. Operators can start with a single module handling basic sorting and washing, then add specialized units as volumes increase. Modular systems allow for incremental investment that matches cash flow generation from initial operations. This phased approach reduces financial risk compared to large upfront investments in fixed-capacity plants. The expansion process for modular systems typically involves simply adding parallel units or supplementary processing modules with minimal disruption to ongoing operations. Many modular systems are designed with future connection points that simplify later capacity increases as recycling businesses grow.

Operational Flexibility and Adaptability

Material Stream Versatility

Modular systems excel at handling diverse and variable plastic waste streams that challenge traditional recycling plants. Individual modules can be dedicated to specific material types, allowing operators to customize their processing configuration daily or weekly. The compartmentalized design of modular systems prevents cross-contamination when switching between different plastic resins. This adaptability proves invaluable for processors dealing with seasonal variations in feedstock composition or exploring new recycling markets. Modular systems can be quickly reconfigured to accommodate changes in municipal collection programs or the introduction of new plastic packaging formats. The ability to process multiple material streams makes modular systems more resilient to market fluctuations than single-focus recycling operations.

Technology Upgrade Pathways

Modular systems facilitate continuous improvement by allowing individual technology upgrades without full plant overhauls. New sorting, washing, or extrusion modules incorporating the latest innovations can be integrated alongside existing units. This modular approach to technology refresh extends the operational life of recycling infrastructure while maintaining competitiveness. The standardized interfaces of modular systems enable mixing equipment from different manufacturers to create optimal processing lines. Operators can test new technologies in a single module before committing to full-scale implementation across their facility. This risk-mitigated innovation pathway helps recycling businesses stay at the forefront of processing efficiency and output quality.

Financial and Space Efficiency

Reduced Capital Requirements

Modular systems lower the barrier to entry for new recycling ventures by spreading equipment costs over time. The pay-as-you-grow model of modular systems matches expenditures with revenue generation, improving cash flow management. Smaller initial module purchases allow businesses to validate their recycling model before committing to full-scale capacity. Many modular systems offer favorable financing options with payments structured around operational milestones. The shared infrastructure between modules (power, water, controls) reduces per-unit processing costs compared to standalone machines. These financial advantages make modular systems particularly attractive for startups, municipalities, and businesses diversifying into recycling operations.

Compact Footprint Optimization

The space-efficient design of modular systems maximizes processing capacity per square foot of facility space. Vertical integration of processing steps within single modules reduces the material handling space required in modular systems. Many configurations allow for outdoor installation of certain modules, freeing up indoor space for value-added operations. The standardized dimensions of modular systems simplify facility planning and future expansion projects. Some modular systems employ stacking or mezzanine arrangements to multiply capacity without increasing their footprint. This compact design makes modular systems viable for urban recycling centers where space is constrained but material volumes are significant.

Mobility and Geographic Flexibility

Relocatable Operations

Unlike fixed recycling plants, modular systems can be disassembled and moved to new locations as feedstock patterns change. This mobility allows operators to follow shifting waste generation centers or respond to regional policy changes. Modular systems enable temporary recycling solutions for construction projects, events, or disaster recovery situations. The relocatable nature of modular systems protects investments against long-term changes in local recycling economics. Some operators deploy mobile modules seasonally to serve agricultural areas or tourist destinations with variable waste streams. This geographic flexibility makes modular systems ideal for testing new markets before establishing permanent infrastructure.

Decentralized Processing Models

Modular systems enable distributed recycling networks that process materials closer to generation points. Smaller modular systems can be deployed at multiple neighborhood locations, reducing transportation costs and emissions. This decentralized approach improves community engagement by making recycling more visible and accessible. Modular systems allow for hub-and-spoke operations where preliminary processing occurs locally before final refinement at central facilities. The scalability of modular systems supports this distributed model by allowing gradual capacity additions at each location as participation grows. Many municipalities find modular systems ideal for phased rollout of new recycling programs across different service areas.

Quality Control and Consistency

Standardized Processing Parameters

Modular systems maintain consistent output quality through precisely controlled, repeatable processes in each unit. The isolated processing environments within modules prevent quality variations caused by cross-contamination or inconsistent operation. Many modular systems incorporate automated quality monitoring that adjusts parameters in real-time to maintain specifications. This consistency proves critical when producing recycled plastics for demanding applications like food contact or medical products. The standardized design of modular systems ensures uniform performance across multiple units in the same facility or different locations. Buyers of recycled materials increasingly value this reliability, giving modular system operators a competitive edge.

Traceability and Documentation

The compartmentalized nature of modular systems enhances material traceability throughout the recycling process. Individual modules can generate processing reports for each batch, creating comprehensive quality documentation. This traceability is particularly valuable for recycled plastics targeting regulated industries or sustainability-certified products. Modular systems often integrate blockchain or other digital tracking solutions that follow materials from intake through final pellet production. The data collection capabilities of modern modular systems support detailed environmental impact reporting for sustainability claims. These documentation features help modular system operators command premium prices for their verified, high-quality recycled materials.

FAQ

How quickly can a modular system be operational after delivery?

Most modular recycling systems can be processing materials within 2-4 weeks of arrival on site with proper foundation and utility connections prepared.

What maintenance advantages do modular systems offer?

Individual modules can be taken offline for maintenance without shutting down entire operations, and standardized components simplify repairs.

Can modular systems handle the same volumes as traditional recycling plants?

When properly scaled with multiple parallel modules, these systems can match or exceed conventional plant capacities while offering greater flexibility.

Are modular systems more expensive than traditional recycling plants?

While per-unit costs may be higher, the reduced capital risk and phased investment typically make modular systems more economical overall.